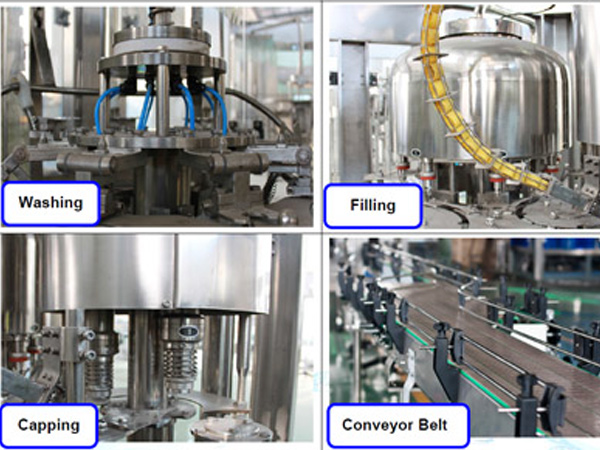

1 liter Auto Filling Machine consist three type of operation; Rinsing, Filling and Capping and they are combined in one unit. Auto Filling can produce 1000 BPH to 6000 BPH of drinking water. Control System is assembled with PLC and Human Machine Interface (HMI) Touch Screen. Included Air Conveyor, Flat Conveyor and Light Checker. This equipment can control Product Capacity Flow Speed.

Overview

3 in 1 Type 8-8-3 Auto Machine.Rinsing-8, Filling-8 and Capping Head 3.This Machine can produce up to 2000 BPH. Include air conveyor and flat conveyor.

- Flow Rate Capacity - 200 BPH - 2000 BPH

- Operation Type – Auto (PLC and HMI Touch Screen)

- Power - 380V , 50 Hz , 3kW

- Rinsing, Filling, Capping Heads - 8 pcs Rinsing head, 8 pcs filling head, 3 pcs Capping Head

- Suitable PET bottle Size - Diameter Ø50 ~ Ø110mm Highness:150 ~ 320 mm, for bottle 250ml - 1500ml

- Suitable to fill - Water & Non-Carbonated Water

- Gross Weight - 2000Kg approximately

- Our company supplies full line of standard and customizable design and build any type of Auto Filling System for water treatment application.

Features:

- This machine works harmoniously with chain plate conveyor belt. it holds the bottles by the neck, thus, reducing the possibility of bottles falling over during conveying process.

- The rinsing station offers through clean water. A simplistic design with minimal parts offers dependable container control and ease of maintenance.

- The filling station using all metal (not plastic) 304 Stainless steel contact parts gives consistent accurate fill levels,& adopts the gravity filling, no drop during filling.

- The place caps style cap-in-head capper station is electromagnetic capping heads, enables dependable container to cap control producing consistent.

More Features:

- Famous Mitsubishi brand PLC and Touch-screen Control Panel (Human machine interface)are adopted, easy operate & working steadily.

- Food Grade stainless Steel rinsing pump & filling pump, reliable & sanitary

- 304 Stainless steel construction, which gives excellent appearance and can be easily disinfected.

- The motor speed is controlled by a variable-frequency-drive, the product rate can be adjusted easily

- The suspending design allows the maintenance to be performed easily due to fewer moving parts.

- Excellent design to making it easily when needs to change machine height when bottles sizes are changed.

- No bottle no filling: no bottle no capping, filling volume adjustable.

Specification

- Capacity - 1000 - 2000 Bottle Per hour on basis of 250-1500ml bottle. adjustable

- Rinsing & Filling & Capping heads - 8pcs rinsing heads, 8pcs Filling heads, 3pcs capping heads

- Suitable PET bottle size - Diameter Ø50 ~ Ø110mm Highness: 150mm ~ 320mm, for bottle 250-2000ml

- Suitable to fill - Water & Non-carbonated drink

- Washing Water Required - 400 Liter to 500 Lire per Hour

- Washing Pressure Equipment - 0.4Mpa

- Filling Pressure - Gravity Filling

- Working Power - 380V AC 50 Hz 3-Phase,(other power supply is available)

- Control Panel Power - 24V DC

- Machine Size - 1750x1550x2250 mm

- Gross Weight - 2000kg approximately

- Total Power – 3.0kW

Application

Can be used in 1 Liter Pure water filling, Mineral water and juices filling.

Service & Maintenance

- We can operate maintenance task on any water treatment technology within our scope of supply.

- Please do not hesitate to contact us for maintenance on your old equipment.

Installation

- We supervise installation and commission every single unit we provide, on client's request.

- We check and maintain our Machine and Water Treatment Solution 1 Time in 2 months.